Understanding the key differences between predictive and preventive maintenance can save your facility thousands in downtime costs while extending equipment life.

The Costly Question Every Facility Manager Should Ask

Your data center’s primary cooling system suddenly fails. Server room temperatures climb quickly, putting critical systems at risk. Even a short period of downtime can cost hundreds of thousands of dollars in lost productivity and revenue, making timely maintenance essential.

These kinds of failures often result from preventable issues in electrical and cooling systems. While traditional preventive maintenance schedules check equipment on a set timetable, predictive maintenance uses real‑time data to anticipate problems before they occur. Facilities that adopt predictive strategies can reduce maintenance costs by up to 30 percent and cut unplanned downtime by nearly half.

The key question for facility managers is which approach best protects critical infrastructure while maximizing operational efficiency.

The Fundamental Difference: Schedule vs. Condition

The core distinction between predictive and preventive maintenance comes down to one key factor: timing.

Preventive maintenance operates on a predetermined schedule. Think of it like changing your car’s oil every 3,000 miles, regardless of whether the oil actually needs changing. You perform maintenance tasks at regular intervals (weekly, monthly, or quarterly) based on manufacturer recommendations and historical data.

Predictive maintenance, on the other hand, is condition-based. It’s like having a smart sensor that tells you exactly when your car’s oil needs changing based on its actual condition, driving patterns, and performance data. Maintenance is performed only when equipment condition indicates it’s necessary.

Why This Distinction Matters for Critical Infrastructure

In mission-critical environments like data centers, hospitals, and manufacturing facilities, the stakes are incredibly high. A single equipment failure can disrupt operations, reduce productivity, frustrate customers, and create serious safety risks. Unplanned downtime also carries a financial cost, with manufacturers losing hundreds of hours annually, and it can jeopardize compliance with regulatory uptime standards.

Understanding the differences between traditional preventive and predictive maintenance is essential for facility managers and operations teams to protect critical systems and minimize risk.

Preventive Maintenance: The Traditional Approach

Preventive maintenance has been the gold standard since the 1950s, and for good reason. It’s straightforward, predictable, and significantly better than reactive maintenance (fixing things only after they break).

How Preventive Maintenance Works

Tasks are scheduled at regular intervals or based on equipment usage, with technicians following standardized checklists and planned downtime windows. Basic condition monitoring may trigger maintenance when certain thresholds are reached, such as UPS battery replacement after a set number of years.

Types of Preventive Maintenance

- Time-based: Maintenance performed at regular calendar intervals (annual HVAC servicing)

- Usage-based: Maintenance triggered by equipment runtime or cycles (UPS battery replacement after 5 years)

- Condition-based: Basic monitoring that triggers maintenance when certain thresholds are reached

Preventive Maintenance Benefits

The main advantages include predictable costs, reduced catastrophic failures, extended equipment life, and compliance with regulatory standards. Preventive maintenance is also easier to implement than advanced predictive systems.

The Preventive Maintenance Challenge

Despite its benefits, preventive maintenance has limitations. Equipment may be serviced unnecessarily, wasting time and resources, or it may need attention before the scheduled interval. Even planned downtime can disrupt operations, and labor and inventory demands are high. Across industries, facilities often spend 30-40 percent more on maintenance than needed by servicing equipment that is still in good condition.

Predictive Maintenance: The Data-Driven Evolution

Predictive maintenance represents the next evolution in maintenance strategy, leveraging modern sensor technology, data analytics, and machine learning to optimize maintenance timing.

How Predictive Maintenance Works

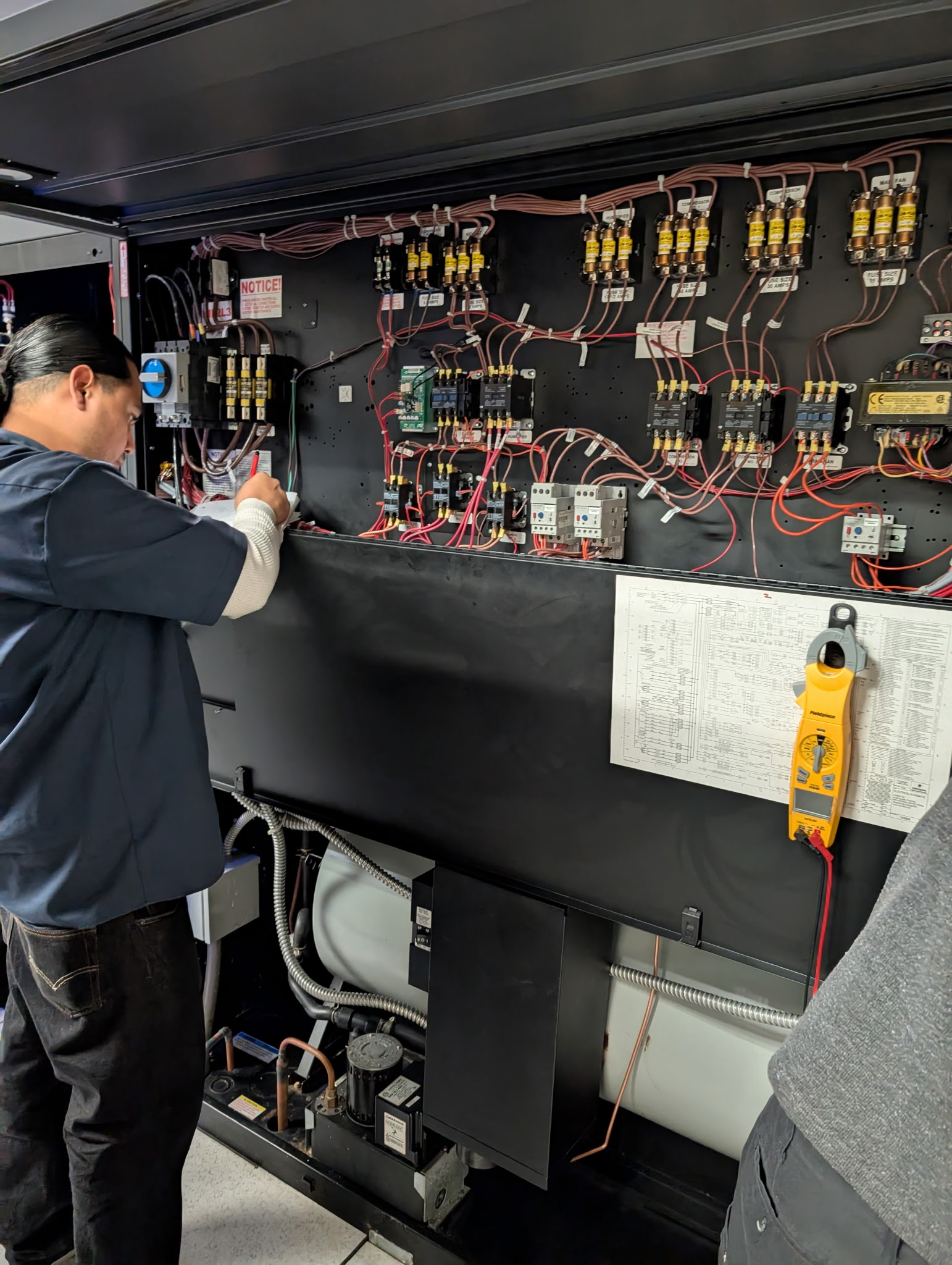

Continuous monitoring collects real-time data on equipment performance, including vibration, temperature, and other key metrics. Advanced algorithms analyze patterns to identify potential issues, while predictive models forecast when equipment is likely to fail. Maintenance is then scheduled based on actual equipment condition rather than fixed timelines.

Key Predictive Maintenance Technologies

Effective predictive maintenance relies on tools such as vibration analysis to detect mechanical wear, thermal imaging for hot spots in electrical and mechanical systems, oil analysis to monitor lubricant condition, ultrasonic testing for leaks and arcing, and motor circuit analysis to evaluate electrical motor health.

Predictive Maintenance Benefits

Predictive maintenance reduces costs by 25-30 percent, cuts unplanned downtime by up to 50 percent, and extends equipment life by optimizing maintenance timing. It also reduces inventory costs by replacing parts only as needed and improves energy efficiency through well-maintained systems.

Real-World ROI: The Numbers Don’t Lie

According to the U.S. Department of Energy, predictive maintenance can yield a 10:1 return on investment. Typical results include 25-30 percent lower maintenance costs, 35-45 percent less downtime, longer equipment life, and energy savings. For a data center spending $500,000 annually on maintenance, predictive maintenance could save $125,000-$150,000 per year while improving reliability.

Side-by-Side Comparison: Making the Right Choice

| Factor | Preventive Maintenance | Predictive Maintenance |

|---|---|---|

| Trigger | Time/usage schedule | Equipment condition |

| Cost to implement | Low-Medium | Medium-High |

| Ongoing costs | Higher (over-maintenance) | Lower (optimized timing) |

| Downtime | Planned, regular | Minimal, as-needed |

| Technology required | Basic tools, checklists | Sensors, analytics software |

| Staff training | Moderate | Extensive |

| ROI timeline | Immediate | 6-18 months |

| Best for | Standard equipment, predictable wear patterns | Critical assets, complex systems |

When to Choose Preventive Maintenance

Preventive maintenance is best for non-critical equipment where failure won’t cause major disruptions, simple systems with predictable wear, and environments with limited budgets that can’t support advanced technology. It’s also suited for regulatory compliance requirements and organizations without the technical resources to run predictive systems.

When to Choose Predictive Maintenance

Predictive maintenance is ideal for critical infrastructure where downtime is costly, complex systems like UPS units, generators, and HVAC systems, and high-value assets where optimization delivers strong ROI. Facilities with technical expertise and those aiming to minimize environmental impact through efficient operations also benefit from this approach.

Implementation Strategy: A Hybrid Approach

The most successful organizations don’t choose between predictive and preventive maintenance, they use both strategically.

The 80/20 Rule for Maintenance Strategy

Most equipment, around 80 percent, can be managed with preventive maintenance for standard, non-critical assets. The remaining 20 percent, consisting of critical and high-value systems, benefits from predictive maintenance. This hybrid approach maximizes ROI while ensuring operational reliability across all systems.

Getting Started with Predictive Maintenance

- Asset prioritization: Identify critical equipment where failure would be most costly

- Pilot program: Start with 2-3 key assets to prove ROI and build expertise

- Technology selection: Choose monitoring solutions that integrate with existing systems

- Staff training: Develop internal capabilities or partner with experienced providers

- Gradual expansion: Scale the program based on proven results and available resources

The Future of Maintenance: What’s Next?

Maintenance is evolving quickly with trends that improve efficiency and reliability. AI and machine learning enable more advanced predictive algorithms. IoT connects facility systems seamlessly. Digital twins create virtual models to simulate equipment behavior, and augmented reality enhances technicians’ capabilities for guided maintenance. Staying ahead of these trends requires a strategic approach while maintaining reliable operations today.

Making the Decision: Your Next Steps

Choosing between predictive and preventive maintenance, or determining the right mix of both, depends on your specific situation. Assess how costly downtime is, which equipment failures would be most disruptive, the resources available for predictive systems, and your organization’s risk tolerance. The best strategy aligns with operational priorities, budget constraints, and risk tolerance while improving reliability and reducing costs.

Moving from reactive maintenance to a proactive approach ensures your critical infrastructure runs smoothly. Contact our team to discuss how the right maintenance approach can improve your facility’s reliability while reducing costs.