Think of your facility’s electrical system like a busy freeway. Cars speed along (the electrons), on-ramps feed traffic (transformers), and highway patrol officers step in to redirect vehicles during accidents. Those “officers” are your switchgear. Without them, you’d have traffic jams, or worse, collisions, every time something went wrong.

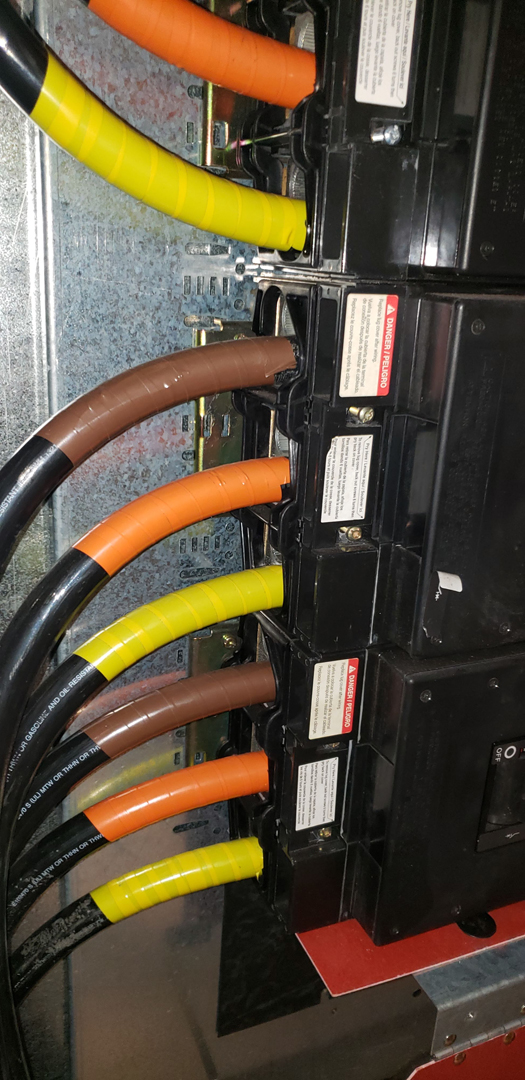

In simple terms, switchgear is a set of disconnect switches, fuses, and circuit breakers in a metal enclosure. Its job? Control where power flows, protect equipment from damage, and isolate sections so technicians can work safely.

“In one Camali data-center project for a Fortune 500 client, a lightning-induced fault tripped a breaker in 20 milliseconds. The site stayed online because the switchgear sensed the fault, opened the breaker, and automatically rerouted power through a redundant path.” — Camali Corp Field Report

This guide explains exactly how switchgear keeps your business running, why it matters for uptime and safety, and what to consider when choosing or maintaining it.

Switchgear 101: A Plain-English Definition

Switchgear is the traffic-cop of your electrical network. It sits between your utility feed and your sensitive equipment. When something’s wrong, it opens or closes circuits automatically to keep power flowing, or stop it, whenever conditions get dangerous.

How Does Switchgear Work?

Switchgear uses protective relays to monitor current and voltage. When a relay detects an overload, short circuit, or other problem, it sends a trip signal. This opens the breaker instantly, stopping the fault. Operators can also open sections manually to isolate equipment for safe maintenance.

Three Critical Jobs: Control, Protection, Isolation

1 – Control — Directing the Flow of Electricity

Switchgear can turn power on or off to different feeders at the turn of a handle or the click of a SCADA (a remote control system for electrical gear) command. This lets facility managers balance loads, run maintenance tests, or shift power to backup sources without shutting everything down.

2 – Protection — Stopping Faults in Milliseconds

An electrical fault can send enormous currents through your system, up to 10,000 amps. That’s like forcing a river through a garden hose. If left unchecked, the heat can melt copper and start fires. Modern intelligent switchgear senses trouble and trips breakers faster than you can blink.

3 – Isolation — Keeping Techs & Equipment Safe

If a transformer needs work, switchgear can “section off” that part of the system. By opening visible disconnects, crews get a clear, grounded air-gap so they can work without arc-flash danger.

Key Types You’ll Meet in the Field

Low-Voltage Cabinets (< 600 V)

Low voltage cabinets, which operate below 600 volts, are the most common type you will see in commercial buildings. They work closely with UPS systems and generator power backups, so they play a major role in keeping essential equipment powered during an outage.

Medium-Voltage Cabinets (1–38 kV)

Medium voltage cabinets cover a much higher range from about 1 to 38 kilovolts. You will usually find them in industrial campuses or utility substations. These cabinets often use vacuum breakers or SF₆ (sulfur hexafluoride) breakers because they can handle larger faults and provide stronger protection.

Metal-Enclosed vs. Metal-Clad

Metal-enclosed and metal-clad switchgear look similar on the outside, but metal-clad units give you an extra safety layer. Each breaker sits in its own compartment, similar to separate rooms. This design helps contain an arc flash so it does not spread to the rest of the gear.

Smart (Intelligent) Switchgear

Many facilities are now upgrading to smart switchgear. These systems have built-in sensors that send real-time current and temperature data to the building management system.

Why Switchgear Matters to Uptime, Cost & Safety

Downtime Math

According to the U.S. Department of Energy, power outages cost the U.S. economy roughly $150 billion per year (DOE 2023). If your e-commerce site loses $5,600 per minute, even a short breaker mis-operation can erase a month’s profit.

Arc-Flash Risk Reduction

IEEE studies report 5–10 severe arc-flash injuries every week in the U.S. Using arc-resistant gear and verifying relay settings greatly lowers both risk and liability.

Energy-Efficiency Opportunities

Modern gear with solid-state relays runs cooler and uses less control power, trimming HVAC load in mission-critical rooms.

Real-World Checklist: Choosing & Maintaining Switchgear

- Get a utility fault-current study

- Choose an interrupt rating higher than your calculated fault

- Confirm UL 1558, NEMA SG-5, or IEC 62271 compliance

- Request arc-resistant features or remote racking

- Schedule infrared scans twice a year

- Exercise breakers quarterly and track the number of operations

- Stock critical spares, some have lead times over 12 months

Camali saved one client $120k in expedited freight by replacing worn contacts during a planned outage instead of waiting for a fault.

Final Takeaways — When to Call the Pros

Switchgear may sit quietly in a back room, but it’s the unsung hero of your power distribution scheme. It controls, protects, and isolates the electricity that keeps your business alive.

If you are growing a data hall, adding UPS Maintenance Services, or need breaker testing, please reach out. Contact our electrical team.

We design, install, and service switchgear that matches your real-world loads and uptime goals.